Tooling¶

The overall purpose of this system is to track the issues and costs of the Tooling equipment used during the manufacturing process to give management the necessary information for making decisions. There are a series of modules, each to perform the task of defining the pieces of Tooling equipment (dies, presses, welders, tow motors etc) in the plant or gathering the data on the activities of each defined item.

Below is a list of the modules found in the Tooling module:

- Tooling Items - Create and maintain the specifics of the tooling items used in the plant. Set maintenance schedules, track Purchase Orders, and review maintenance history.

- Preventative Maintenance - Manage all planned maintenance items in the system.

- Tooling Timecards - Create timecards to record the activities (time and materials) performed on each of the defined items.

- Tooling Requests - Controlling the activities of the Tool Room.

- Manage Tooling Requests - Review of the incoming requests from the W/C Operators. Automatically receives all ‘Tooling Requests’ entered by a W/C Operator.

- Reports - Various reports summarizing the gathered information.

- Admin - Establish system parameters to gather and report the information including: Tool Room Priorities, Scheduled Maintenance Reasons, Tool Types, Storage Locations Tooling Checklist Items, and Tooling Reason Codes.

Operator Schedule and the Tooling Module¶

The Operator Schedule screen and the Tooling module are integrated in the ShopEdge system.

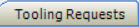

There are three tabs on the Operator Schedule screen that pertain to the Tooling module: the  tab, the

tab, the  tab, and the

tab, and the

tab.

tab.

Note

For more detailed information regarding the Tooling, Tooling Requests, and Tooling Tips tabs, please see Production > Operator Schedule > Job Details.

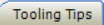

Tooling Tab¶

The Tooling tab lists all of the Tooling Items with details of the Tooling Items linked to the highlighted Job in the above section of the screen.

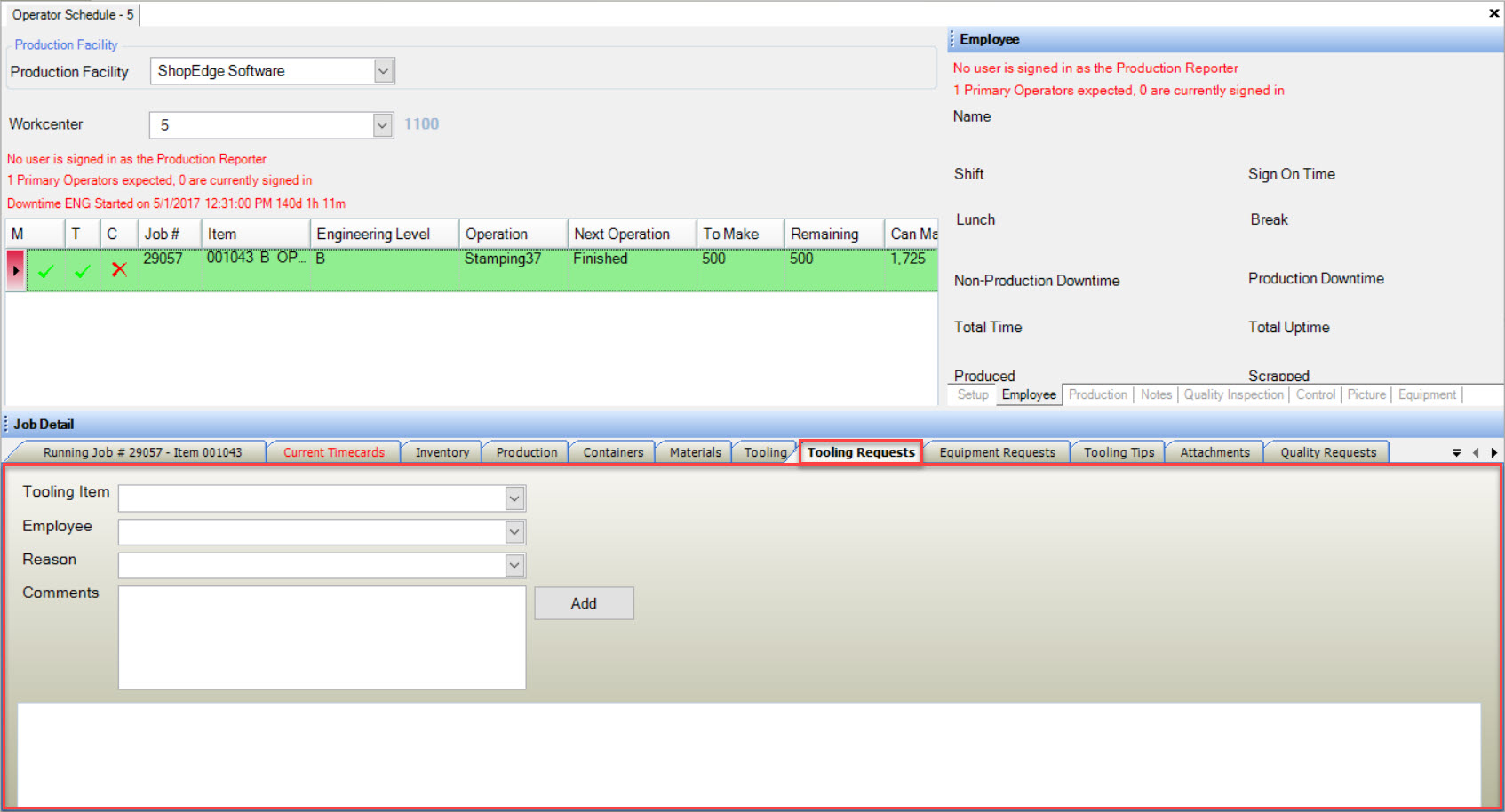

Tooling Requests Tab¶

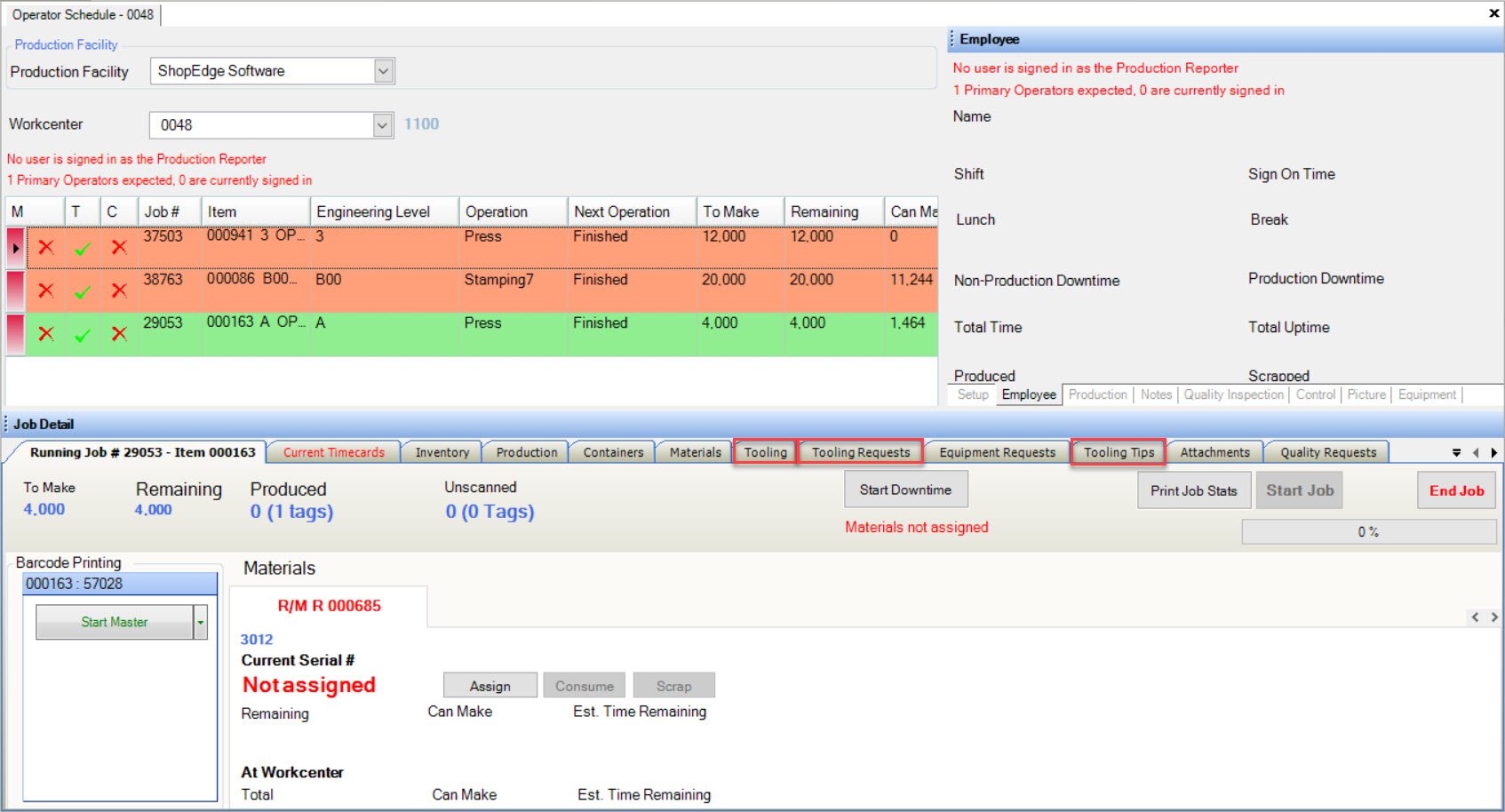

The Tooling Requests tab is used by Operators to record issues regarding the Tooling part or item meeting certain specifications. As each Tooling Request is added to the list, they are then displayed in the Notes section.

To add a Tooling Request on the Operator Schedule, make sure to select a Tool, Employee, and Reason code by using the available drop-down menus. Then, enter in any necessary comments. Click on the

button to add the Tooling Request to the list.

button to add the Tooling Request to the list.

The Tooling Request is then recorded and viewed in the Tooling module under the ![]() icon.

icon.

Note

Tooling Requests can also be created directly in the Tooling module under the ![]() icon.

icon.

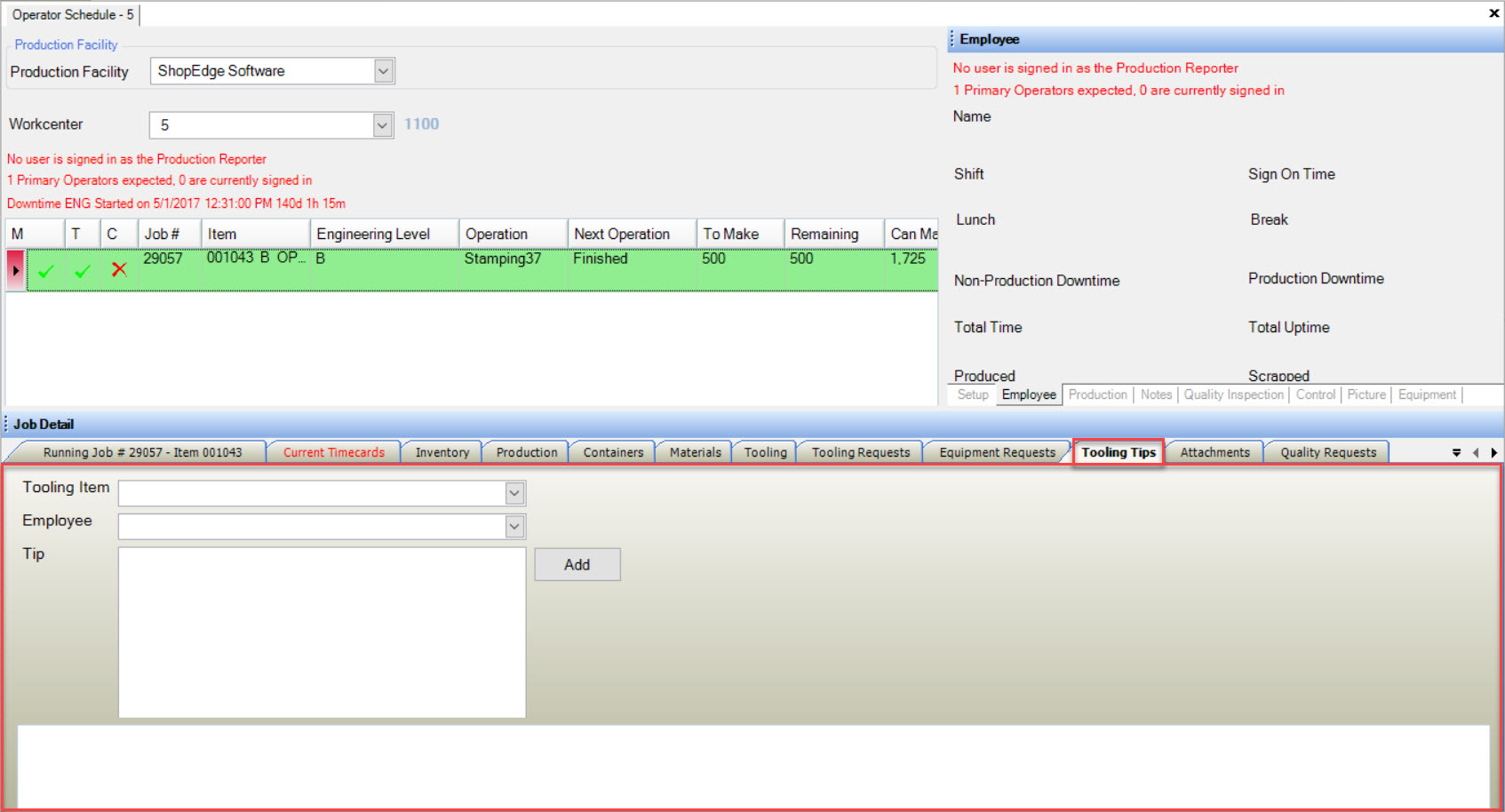

Tooling Tips Tab¶

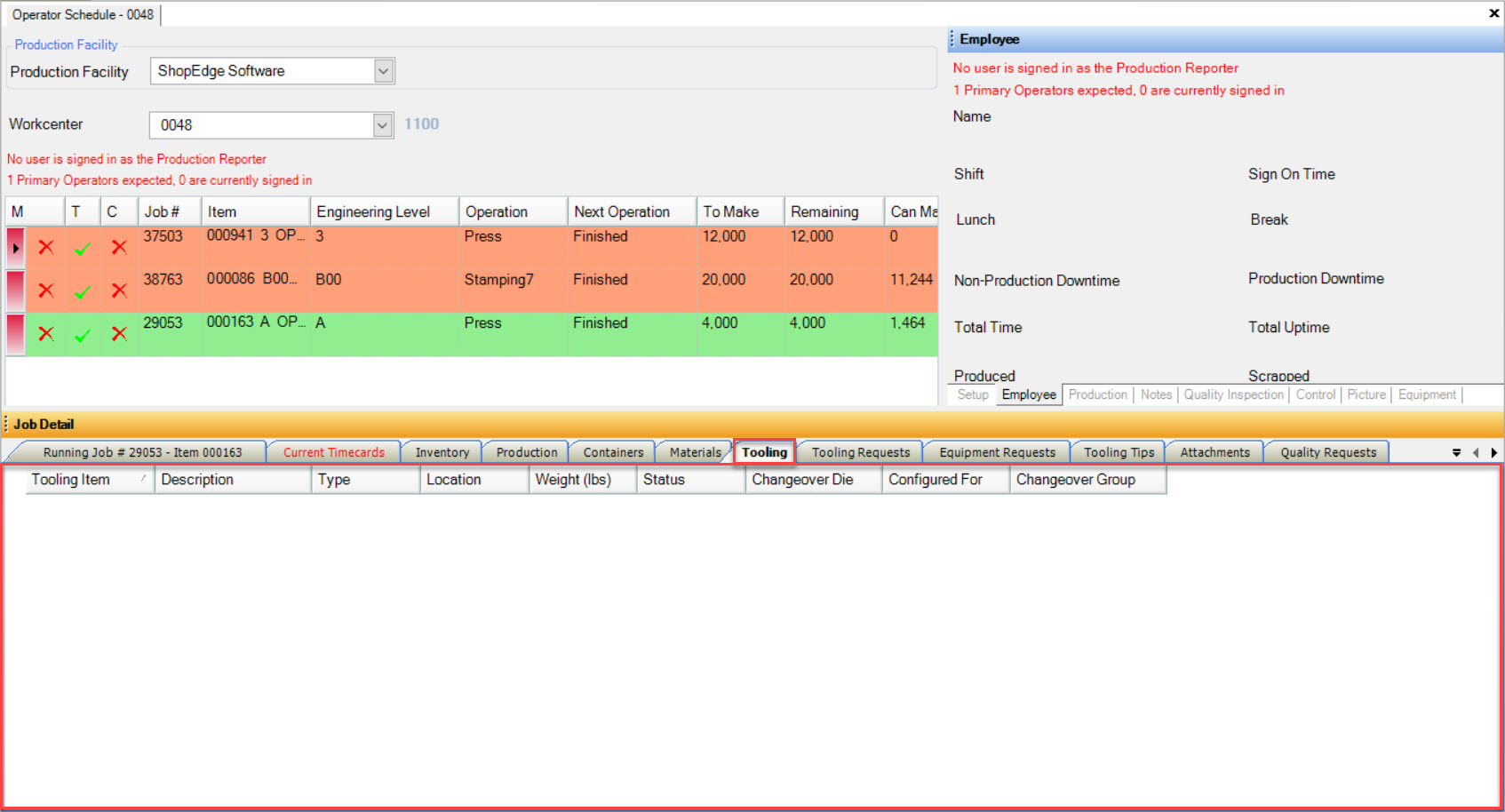

The Tooling Tips tab is a communication mechanism on how to deal with any Tooling issues or tips on how to run the Job at it’s maximum potential. These Tooling Tips are displayed below and stay in display until manually removed by the Tooling Manager under the Tooling Requests function under the Tooling module.

To add a Tooling Tip on the Operator Schedule, make sure to select a Tool and Employee, and complete the Tip textbox. Then, click on the  button to add the Tooling Tip

to the list.

button to add the Tooling Tip

to the list.